The Ministry of Finance has clarified that projects affected by the Coronavirus breakout would be given relief by way of extensions in project completion timelines under Force Majeure provisions. The announcement is not a surprise as the resultant business disruption, clearly outside the control of the project developers or the equipment suppliers, has severely impacted equipment shipments and installation activity. Module, inverter and other material shipments are delayed across the board and there is no clear visibility over how long the disruption would last.

- China’s stranglehold over sector supply chain means that project developers and equipment manufacturers across the world have been hit hard by this disruption;

- Despite the Force Majeure relief, projects under execution would be adversely affected due to increase in equipment and other operating costs;

- This incidence is a stark reminder of risks arising due to heavy reliance on just one country but it is important that the right policy lessons are learnt;

China’s manufacturing dominance extends across the value chain including wafers, cells, backsheets, chemicals, adhesives and electrical components. Its stranglehold over the supply chain means that even manufacturers in other countries are having to curtail operations.

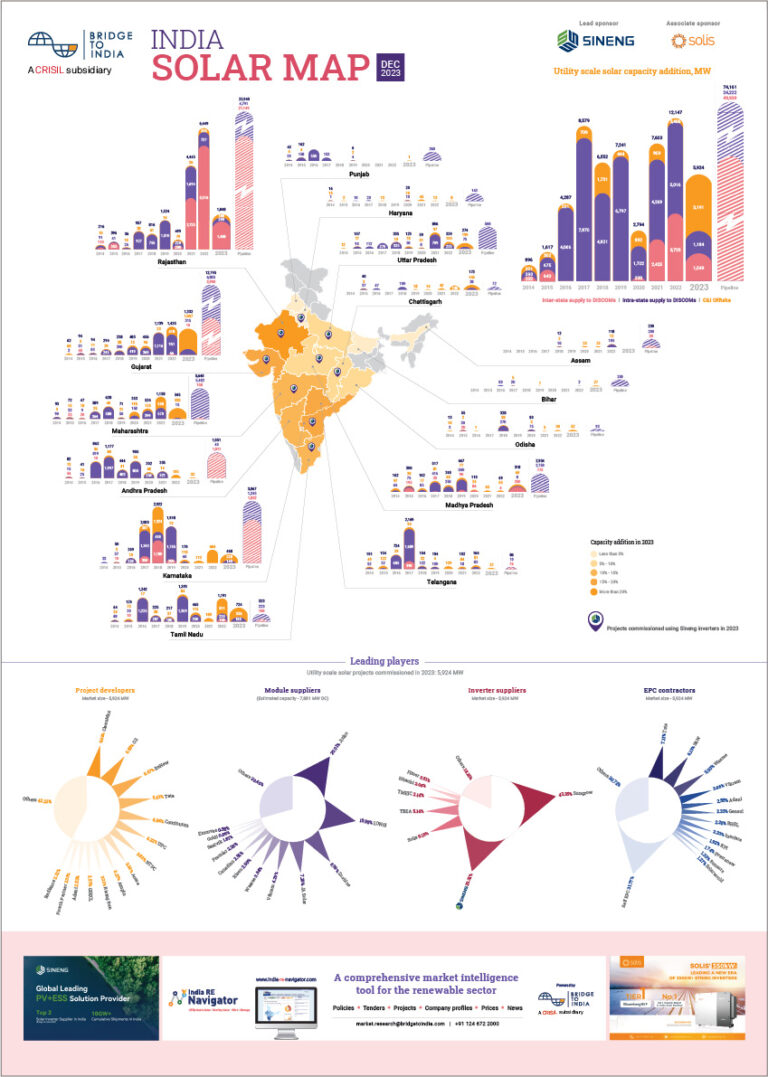

Figure: Module and inverter suppliers for utility scale solar projects commissioned in 2019

Source: BRIDGE TO INDIA research

Based partly on a quick round of checks with various market players, our assessment is that different players would be affected very differently. For utility scale projects, commissioning is likely to be delayed across the board due to heavy reliance on imports from China (see chart). Module prices have also firmed up rather than falling as expected earlier. Associated increase in other costs including working capital, interest charges etc. would mean that notwithstanding the Force Majeure relief, the final impact would still be damaging. Even in an optimistic scenario, there are fears that normal service may not resume for another 2-3 months as the Indian developers may lie at the back of the queue because of low price expectations.

Rooftop solar, which typically enjoys a very busy Q1 (end of the financial year), is affected badly with installation volumes down as much as 40-50% over normal levels. Indian module manufacturers are also badly affected despite stocking up on supplies in advance of the Chinese new year. But they should be able to revert to full operations faster than other players.

The loud and clear message from this episode is that supply chain control is fundamentally important for real energy security. But all those calling for more trade barriers should note that the disruption is affecting not only solar projects (across the world) but also most parts of the economy including electrical and electronics, automobiles, engineering goods, tourism, amongst others. We need a wider economic reform and a vigorous industrial policy to improve long-term competitiveness of domestic manufacturing.