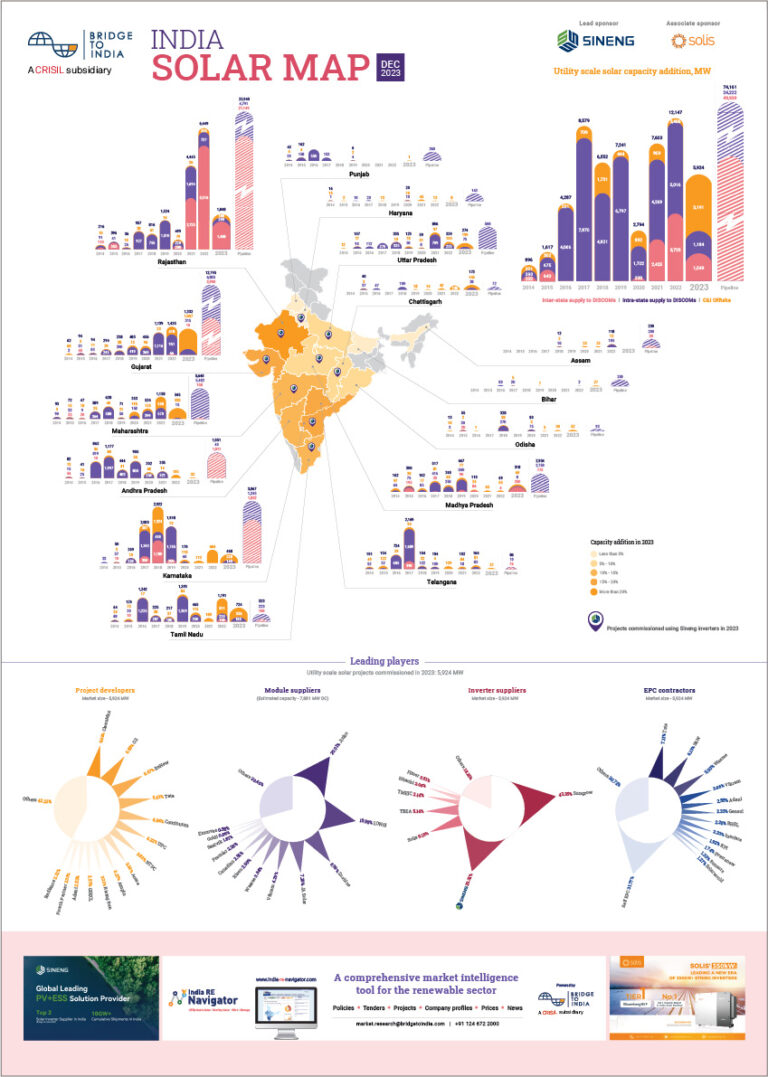

Global solar demand is expected to fall for the first time ever this year – to about 85-90 GW from 103 GW last year. Most of the leading countries including China, India, US and Japan are reporting significant declines in capacity addition. Result – multi-crystalline module prices have fallen to USD 0.22/ W, down nearly 40% in the last nine months and are predicted widely to fall further to USD 0.18-0.19/ W by Q2 next year. This price crash is having a profound impact on the entire sector value chain.

- Bigger module manufacturing players are breaking away from the industry by expanding aggressively and investing in new technologies;

- There are question marks over long-term survival prospects of smaller players;

- In a fast-moving industry subject to fierce pressure, the project developers need to be extra cautious in choosing equipment suppliers;

It is difficult to know how the module manufacturers will ride out these tough conditions. On one hand, the industry is getting consolidated with a new ‘super league’ of players with 5-10 GW of global capacity. At the same time, aided in part by China’s Top Runner programme, some players (LONGi, GCL, Tongwei) are making aggressive investments in new technologies and expanding their footprint. The module technology landscape, dominated by plain multi-crystalline modules for long, is suddenly looking like a rainbow. Development of new technologies and form factors – n-type, mono and mono-PERC, half-cut cells, IBC, HJT, bifacial, frameless and glass-glass modules – is adding complexity to the business. And even though the module players have benefited from large price falls in upstream polysilicon industry (see chart below), it is feared that many of the smaller tier-2 and tier-3 players in China may undergo a financial collapse. But that is dependent on Chinese government policy and plans for the sector (there are some talks that China may increase its 2020 solar target by as much as 60 GW).

Figure: Module manufacturing value chain, USD/ W

For the project developers, changes in the module industry pose all kinds of challenges. At a recent conference, some developers seemed confused – they were unhappy that the module manufacturers are pushing new technologies and products without proven track record. Some even complained that project design process is becoming too cumbersome as they have to run multiple design configurations. More pressing concerns relate to quality, bankability and after-sales service in a fast-moving industry subject to fierce price pressure.

Nonetheless, the Indian developers, facing their own viability challenges, are increasingly buying (cheaper) modules from relatively smaller and/ or unknown players. The short-term price focus may not be a wise move in these times.

Figure: Market share of module suppliers in Q3 2018

Source: India Solar Compass Q3, 2018, BRIDGE TO INDIA

Note: This data is for utility scale projects commissioned in the quarter.