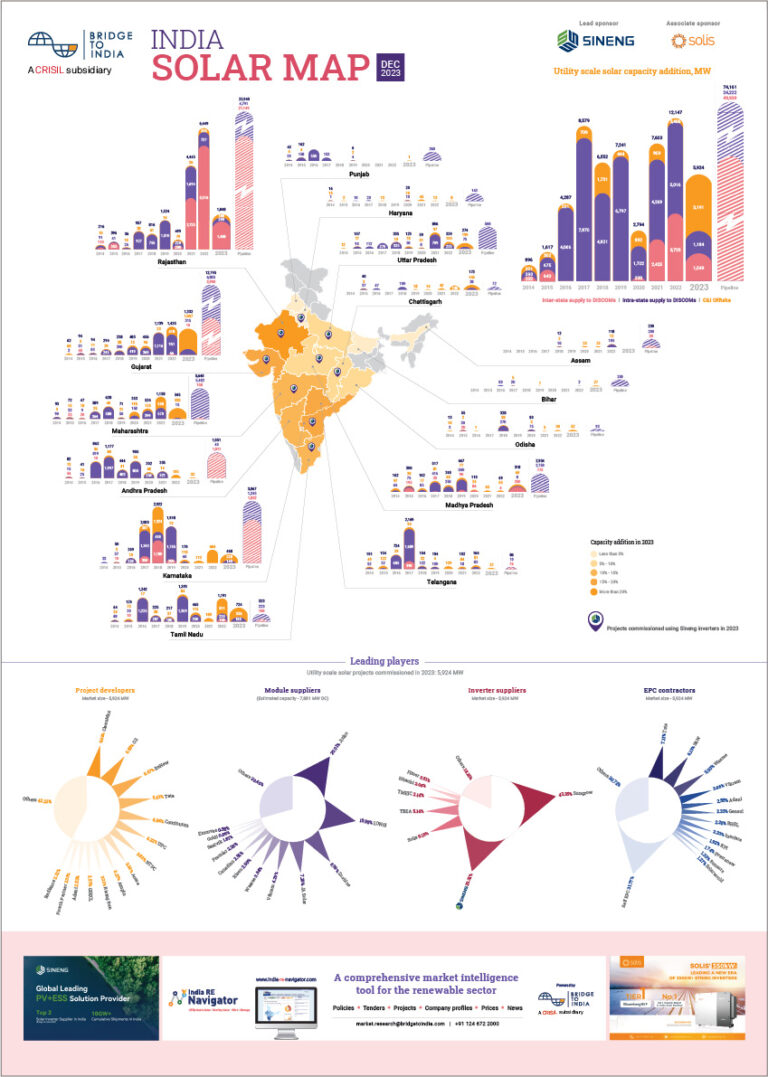

In the midst of increasing competition, falling tariffs and shrinking profit margins, the market for solar trackers picked up sharply in India in 2017. Developers were increasingly keen to use trackers to enhance project performance to maximize returns. Commissioned capacity using trackers increased from 86 MW in 2016 to 1,427 MW in 2017.

India being one of the largest and fastest growing solar markets around the world, is also expected to be an attractive market for trackers. However, a sharp 25% reduction in module prices over last few months has been a setback. Tracker installations in H1 2018 reduced to 246 MW and are estimated at 380 MW in the entire year.

Figure: Solar tracker installations in India

At lower module prices, it is more beneficial to increase DC:AC overloading (ie. deploying additional modules) rather than using trackers to enhance project performance. Fall in module prices has also unfortunately coincided with increase in price of steel, which accounts for more than 70% of cost of trackers, further dampening market prospects.

Slowdown in demand has led tracker suppliers in India to change their strategy. US-based NEXTracker, the second largest supplier in the Indian market, has put on hold its plans of setting up a domestic manufacturing facility. Indian companies like Mahindra Susten and Scorpius, which together hold a 32% market share, are investing in structure redesign and arranging for cheaper steel supplies to reduce cost of production. Moreover, they are increasingly relying on exports to make up for reduced demand in the domestic market.

However, one significant advantage of trackers is getting overlooked in India. Trackers reduce peak power generation and instead increase output in the morning and evening hours. In other words, they make the generation profile flatter, thereby reducing variability of power output and enhancing grid stability. This feature is highly valuable but the Indian market design is unfortunately completely focused on delivering lowest cost of power.