It has been described as the perfect storm. A mix of global economic rebound after COVID demand slump and trade disruptions has sent energy prices skyrocketing. International prices for coal (USD 150/ tonne), natural gas (USD 5.7/ MMBTU) and crude oil (USD 75/ barrel) have surged by as much as 15% in the last month to reach annual highs.

Figure: Prices of coal, crude oil and natural gas, USD

Source: BRIDGE TO INDIA research

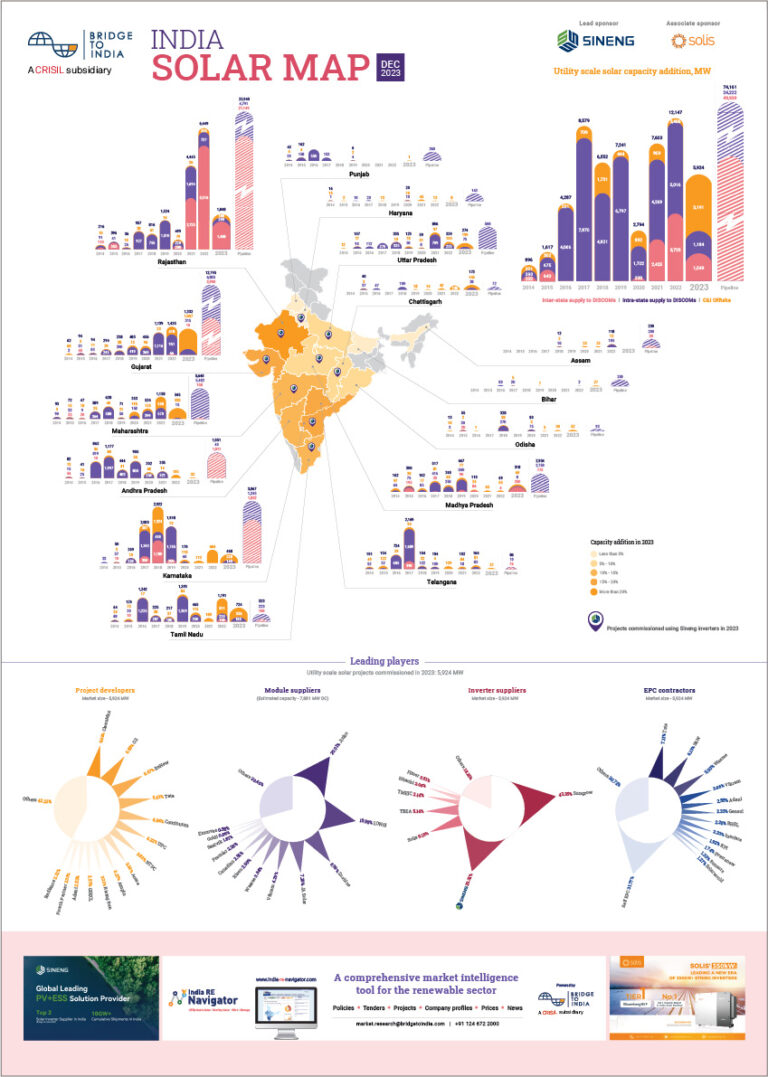

In parts of China, power consumption is up over pre-pandemic levels by as much as 15% and is set to escalate further with onset of winter. Supply situation has worsened due to curbs on Australian coal imports and heightened safety protocols after a series of industrial accidents last year. Recent attempts to rebalance the economy away from fossil fuels and a new commitment to cut carbon intensity, by more than 65% from 2005 levels by 2030, have aggravated the crisis. China has begun rationing energy to provinces and is setting them consumption reduction targets. According to a leading Chinese module manufacturer, manufacturing operations have been curtailed at over 1,000 companies since last month – hampering output across the solar value chain.

Struggling to cope with curtailed power supply and higher costs, solar manufacturers are both cutting back production volumes and raising prices. Silicon prices have risen by 147% month-over-month, while polysilicon prices have moved up by a further 40% in the same period. EVA sheets, in short supply, have seen a 33% price increase over previous month. Manufacturers are quoting mono-crystalline module prices at USD cents 28/ W, up more than 10% since July 2021, although supply timetable is far from clear. China-India freight costs have jumped up even further to USD 9,000 per container, up over 10x in just over a year.

Figure: Spot prices of mono-grade polysilicon, wafers, cells and modules, USD

Source: PV Infolink, BRIDGE TO INDIA research

Five leading Chinese module manufacturers have issued an unprecedented call asking their customers to delay project timelines. Indian project developers have received force majeure notices intimating them about delayed shipments and higher prices on already signed contracts.

We estimate that Indian developers are planning imports of about 6-8 GW over the next six months ahead of BCD implementation. It is a desperate situation for these developers – escalating costs, no clarity on timelines, delays adding to further costs and, risks of penalties and additional duties. The crisis seems likely to last until Q2 2022 with huge uncertainty ahead on project execution timelines as well as costs. Blindsided by these developments, the developers are planning to seek relief from government on both fronts.

Some analysts have blamed China for the negative turn of events, but we believe that there are many other factors including economic and policy volatility, trade barriers and energy transition contributing to the crisis. Boosting domestic solar manufacturing capability would help but renewable sector should, in general, be better prepared for greater uncertainty ahead.